As businesses strive for agility and operational efficiency in today’s fast-paced market, supply chain control towers’ advanced systems offer essential real-time visibility that allow organizations to make informed decisions quickly.

The effectiveness of supply chain control towers lies in their ability to monitor end-to-end operations, identifying bottlenecks and enabling immediate responses to disruptions. This agility not only improves inventory management but also provides a significant competitive edge.

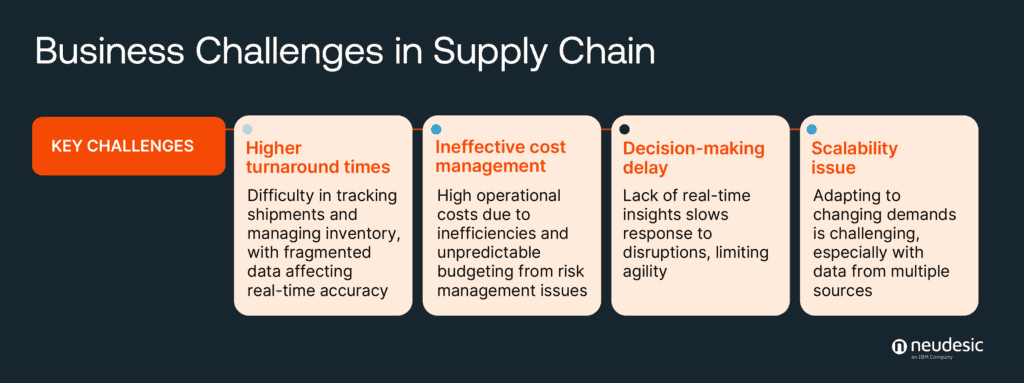

Business Challenges in Supply Chain and Inventory Management

Despite the ever-growing necessity for efficient operations, the supply chain sector faces persistent challenges. These hurdles consistently impact efficiency, cost management, and scalability. Addressing these challenges is essential for organizations aiming to build resilient, cost-effective supply chains that can adapt to market shifts.

Key Challenges

1. Higher turnaround times

Tracking shipments and managing inventory effectively continue to challenge many organizations. Inconsistent data across systems creates fragmented information, making it more difficult to achieve the real-time accuracy that organizations rely on for smooth operations, increasing turnaround times.

2. Ineffective cost management

Commonly, inefficiencies across the supply chain may lead to high operational costs. In addition, a limited ability to predict and mitigate risks can further increase expenses, make budgeting unpredictable, and secure procurement at higher costs.

3. Decision-making delay

Without a comprehensive, real-time visibility, supply chain teams often struggle to find the insights needed to respond quickly to unexpected disruptions. This can hinder agility and prevent organizations from proactively addressing issues.

4. Scalability issue

As consumer behaviors change, supply chains must adapt to new demands, but scaling operations smoothly often proves difficult. Managing data from multiple sources compounds this challenge, making it harder to create a cohesive, responsive strategy.

What is a Supply Chain Control Tower?

An optimal way to address supply chain challenges is through a supply chain control tower. A supply chain control tower is a comprehensive solution that integrates data across the entire ecosystem, providing end-to-end visibility and actionable insights. This solution enhances service levels while reducing costs. A supply chain control tower is utilized to refine production schedules, secure procurement cost-effectively, and improve inventory management and turnaround times to enhance scalability.

Key Capabilities of Supply Chain Control Towers

To ensure successful implementation, supply chain control towers should have the following key capabilities:

1. Real-time visibility to scale

Real-time dashboards for tracking end-to-end key performance indicators that include production rates and inventory levels and monitoring risks and bottlenecks through risk alerts, transit delay alerts, and equipment failure identification.

2. Impact analysis to improve cost management

Root cause analysis on inventory overstock as it pertains to order delays and impact analysis on impact of transit delay on revenue to reduce operational expenses.

3. Simulation response to enhance decision-making

Scenario modeling for evaluating alternative sources in case of constraints and alternative recommendations.

4. AI-driven intelligence for forecasting

AI-driven recommendations for optimal inventory management as well as predictive and prescriptive maintenance to forecast future production levels.

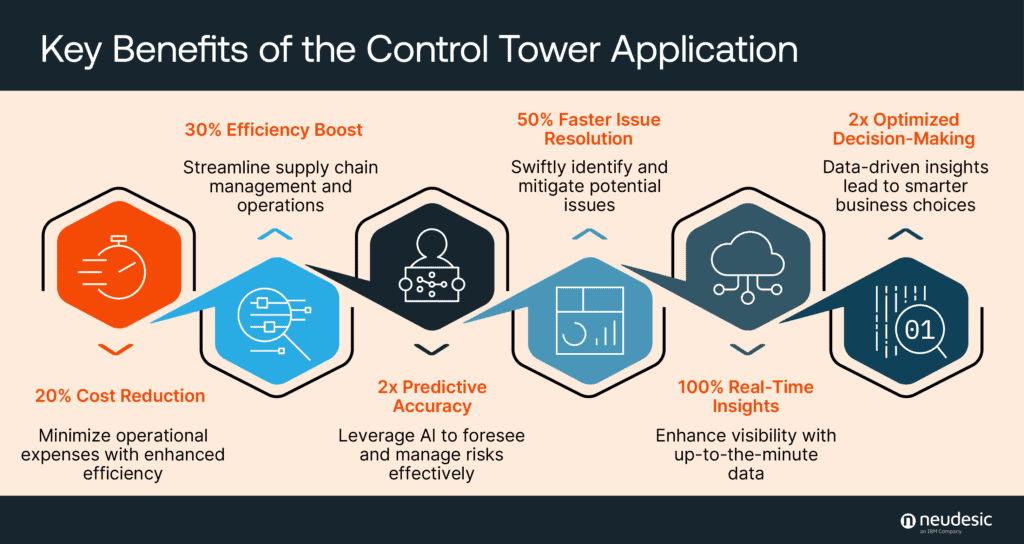

Benefits to Supply Chain Control Towers

Supply chain control towers offer a transformative approach to managing and optimizing business operations, providing a level of visibility and control that traditional systems cannot match. The key benefits of implementing a digital control tower are vast and multifaceted. Below, we outline the most significant advantages that come with adopting these cutting-edge systems, from unifying operations to enhancing decision-making and anticipating risks. Each of these points highlights how supply chain control towers create more efficient, responsive, and informed business environments.

1. Optimized Operations

2x Predictive Accuracy: Break the cycle of constant reactive measure through advanced predictive tools and analytical models designed to preempt issues.

2. Cost Efficiency

20% Cost Reduction: Deliver accurate and repeatable outcomes through an automated, consistent solution, replacing the variability of manual, ad hoc processes.

50% Faster Issue Resolution: Identify risks early through proactive detection and alert systems, preventing them from escalating into costly, resource-draining emergencies.

3. Enhanced Decision-Making

2x Optimized Decision Making: Address immediate business challenges through agile data models and tools, bypassing the complexities of outdated legacy systems.

100% Real-Time Insights: Enable swift, informed decision-making through real-time monitoring that ensures immediate visibility into critical processes

4. Improved Scalability

30% Efficiency Boost: Streamline supply chain management and operations through a comprehensive and synchronized view. A single interface streamlining data sources into one coherent system, eliminating the need to navigate through fragmented reports and disjointed analyses.

Key Considerations for Successful Implementation

To build a highly efficient and future-ready supply chain control tower, several key strategies must be implemented:

1. Extract, Integrate, and Model Data

In today’s data-driven landscape, information resides across multiple applications, ERP systems, and different data exchange formats. Leveraging advanced frameworks to consolidate this data is key to building smart platforms that enable both self-service analytics and curated analytics. By creating robust data products and enhancing data access and search capabilities, organizations can unlock the true potential of their data assets.

2. Emphasize Data Governance and Quality

Maintaining the integrity and security of data is a cornerstone for accurate and reliable decision-making. Implementing strong data governance frameworks ensures that data remains consistent and secure, laying the foundation for effective control tower operations.

3. Adopt Iterative Design for Accelerated Benefits

To futureproof supply chain control towers, capabilities must evolve incrementally. Building and enhancing functionality through iterative design ensures continuous improvement and faster realization of business benefits, aligning with shifting business priorities and technological advancements.

4. Leverage Advanced Frameworks and Best Practices

Agile delivery methods allow for rapid, iterative development of control tower solutions. Focusing on the efficiency of data ingestion, storage, and consumption processes ensures that data flows seamlessly through the system, providing timely and actionable insights. In addition, integrating well-defined frameworks in essential areas such as data ingestion and governance, as well as AI/ML modeling, enhances system capabilities. Self-service data management tools empower users to independently access, analyze, and use data, improving productivity and decision-making across the board.

5. Incorporate Cutting-Edge Technologies

Integrating the latest innovations such as the Internet of Things (IoT), AI, and digital twins is essential for building a comprehensive and forward-thinking supply chain control tower. These technologies enhance real-time monitoring, predictive analytics, and simulation capabilities, providing a more dynamic and responsive solution to manage complex operations.

6. Drive User Engagement and Adoption

Engaging key stakeholders from the outset and offering thorough, ongoing training is critical to ensure the successful implementation and widespread adoption of supply chain control towers. Early involvement fosters alignment, while effective training equips users to fully leverage the system’s capabilities, ensuring long-term success.

Optimize Operations with Neudesic’s Supply Chain Control Tower

With more than 20 years of experience in advancing businesses with Microsoft technology expertise, Neudesic leverages AI to drive analytics that optimize supply chain operations. Neudesic’s Supply Chain Control Tower is a cloud-based application that provides businesses with end-to-end visibility and control over their operations. By integrating various systems and data sources, it offers real-time insights, predictive analytics, and actionable intelligence to optimize performance. Neudesic’s Supply Chain Control Tower helps organizations optimize service levels while lowering operational costs and supporting better decision-making across logistics, supply chain, and warehouse management.

Conclusion

Supply chain control towers are set to revolutionize operations across multiple industries, leveraging advanced technologies such as AI, the Internet of Things (IoT), and digital twins. By enhancing real-time visibility and operational efficiency while enabling proactive risk management, these systems are poised to transform the way businesses operate in an increasingly complex digital landscape. As organizations integrate these capabilities, they will not only improve service delivery but also significantly lower operational costs, ensuring a competitive edge in supply chain.

To learn more, visit https://www.neudesic.com.

Related Posts